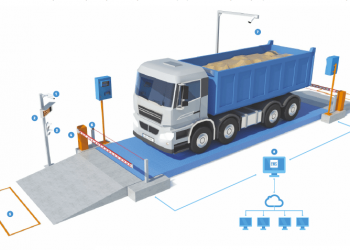

The Semi Automatic Weighbridge System is a stand alone system which allows 24 hours 7 days a week weighing

operations. Due to the system’s easy interface it is totally operated by the truck driver. Moreover Sasco custom designs the system to suit the specific requirements of your operations.

SASCO ENGINEERING COMPANY – Provide Two Way Weighment System on weighbridge means vehicle enter both side forweighment also we can pre fix weighbridge for weighment if they try another weighbridge system cannot allow toweighment.

As complete information is scanned through PLC Controller & Camera Software which reduces the

operation cycle and prevents the manual entry errors. The system makes the weighment process highly secure by allowing integration with IP cameras, and traffic lights for capturing images during the weighment, managing vehicle traffic, vehicle queue management and carrying out safe operation. The system further integrates with ERP systems like SAP and Tally to remove

errors due to manual entries.

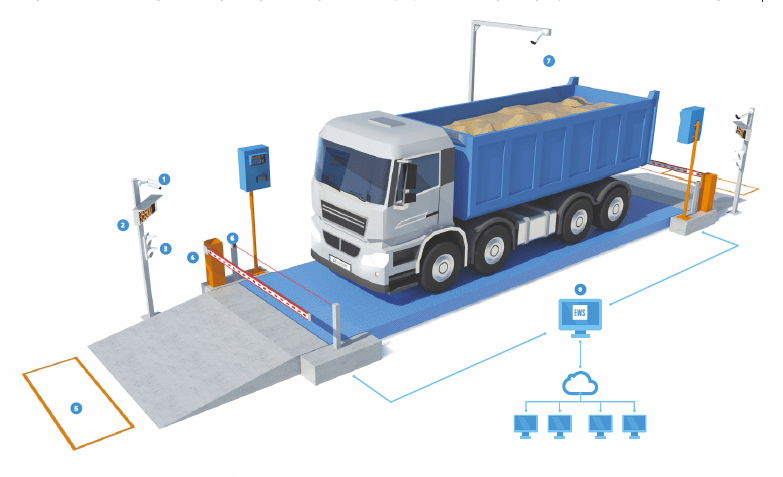

If you wish to identify the vehicle automatically, either to enter its registration number into the weighing record or to compare it with that held on the system against the RF Tag or Data key Rotec can offer a fully automatic number plate recognition system. A camera (ANPR) is trained on the vehicle and by using optical character recognition is able to feed the registration number into the computer to be logged against the record being written.

If the RF tag or data key has a vehicle or vehicles associated with it and the number read by this system is not one of those, then the computer can take appropriate action, such as logging a warning or alerting Security

This automation system is use full for vehicle position on weighbridge. system integrate with PLC Based Intelligent

terminal, that terminal manage photo censor and find out vehicle position and make further process for weighment.

System provides solution for Vehicle Photo Capture at Weighment time and Save on HDD. also System Provide Photo Viewer Facility, so we can check later one that photo, also System Store photo with this detail like – Ticket No / Date / Time / Entry Type (First/Second). So we easily find out vehicle photo for particular Ticket No.

System provide best solution as per customer require with weighbridge like,

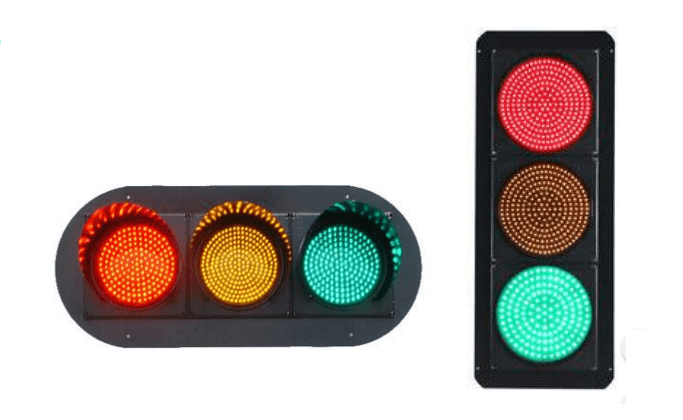

We provide Best Quality LED Traffic light With Green Color, Red Color. in 12 Volt DC, 24 volt DC, 230 AC…. With

Various Dia Like 100 mm, 200 mm, 300 mm…..

Provide Customize LED Traffic lights With Customize Light with Various color.

Description:-